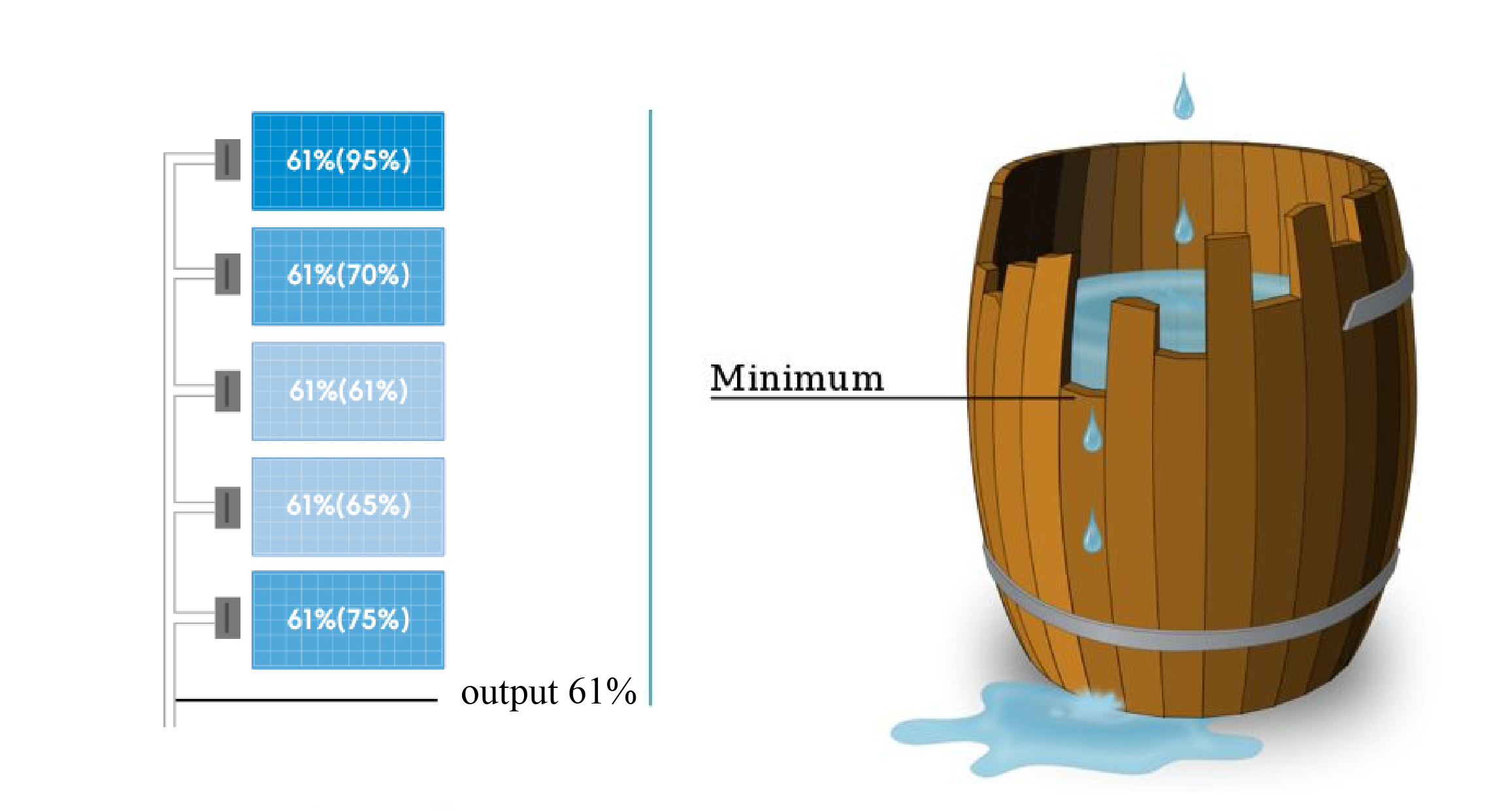

In a PV system, modules operating in series are like a chain linked one after another. If any single module underperforms, it can drag down the efficiency of the entire system. This is what’s known in the PV industry as the "bucket effect" — the power generation capacity of the whole system is often determined by the worst-performing module. The PV optimizer was created to break this limitation. Let’s use a specific model to explain in detail.

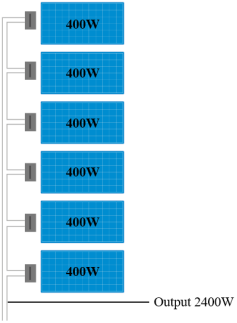

Imagine a PV string made up of 6 modules connected in series. In a perfectly ideal environment — no shading, uniform aging, and matching performance parameters — all modules operate efficiently under the same light conditions.

At this point, each module outputs a stable current of 10A (actual values may vary slightly based on module specifications) and operates at 40V. Using the power formula (Power = Current × Voltage), the power output of a single module is 10A × 40V = 400W. Since the modules are in series, the current remains consistent across the entire string. Thus, the total power of the 6 modules is 6 × 400W = 2400W — the best possible performance for this string in ideal conditions.

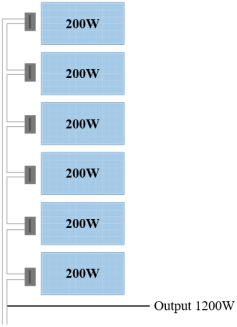

In practice, however, PV systems rarely stay in ideal conditions. Issues like tree shade, building shadows, dust accumulation on modules, or localized aging can degrade the performance of a single module, turning it into a "weak link" that slows down the entire system.

For example, if one module is covered by shade, its output current drops sharply to 5A. Due to the nature of series circuits — current is the same everywhere — the other 5 normally functioning modules are forced to operate at 5A as well. Each module’s power then drops to 5A × 40V = 200W, and the total power of the entire string falls to 6 × 200W = 1200W, only half of the ideal output.

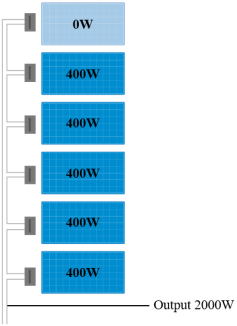

To mitigate this, PV modules are typically equipped with "bypass diodes." When a module malfunctions, the diode "bypasses" it (i.e., skips the module), allowing current to flow directly through the others. In this case, the bypassed module stops generating power, while the remaining 5 modules can resume normal operation at 10A, resulting in a total power of 5 × 400W = 2000W. While better than the previous scenario, one module’s power is completely wasted, leaving room for improved system efficiency.

The core function of SUNGO’s PV optimizer is to enable each module to "contribute its best" without letting individual module issues affect the whole system. It monitors the operating status of each module in real time and precisely adjusts voltage and current, allowing problematic modules to retain as much of their power output as possible without dragging down others.

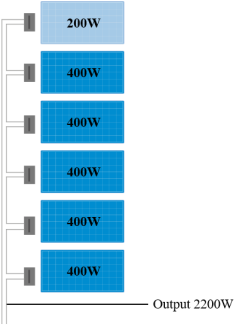

Let’s return to the shaded scenario: The shaded module originally outputs 5A at 40V, totaling 200W. With a PV optimizer installed, the optimizer reduces the module’s voltage (from 40V to 20V) while increasing its current (from 5A to 10A), keeping its power output at 200W (10A × 20V = 200W). The other 5 normal modules remain unaffected, operating at 10A and 40V to maintain 400W each.

Ultimately, the total power of the string is 200W (shaded module) + 5 × 400W (normal modules) = 2200W. This is 200W more than the bypass diode solution and 1000W more than the unoptimized scenario, significantly reducing power loss caused by "weak links."

Through such targeted adjustments, PV optimizers effectively overcome the "bucket effect" in PV systems, enabling each module to maximize its value under its own conditions. They are particularly suitable for complex, easily shaded scenarios like rooftops and mountainous areas, providing strong support for the efficient and stable operation of PV systems.